What we do

We specialise in the development and production of components, sub-assemblies and systems in steel and light alloys.

Technologies

We use state-of-the-art technologies to ensure precision, efficiency and reliability at every stage of the production process.

ROBOTIC ASSEMBLIES FOR THE SUPPLY OF SYSTEMS AND SUB-ASSEMBLIES

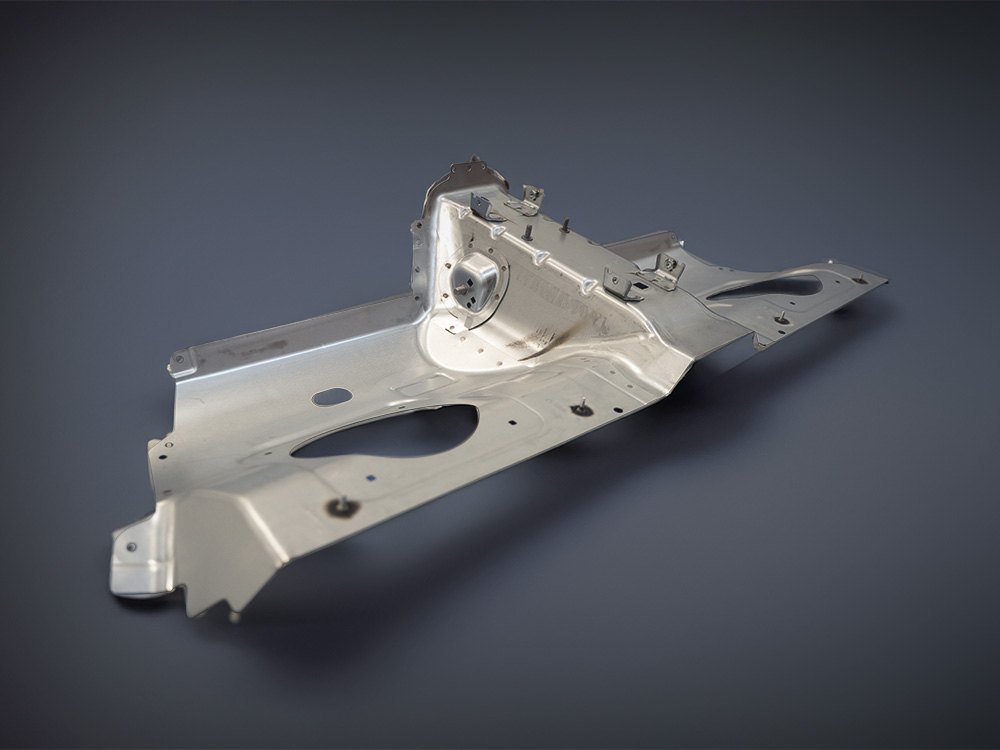

COLD MOULDING OF

- STAINLESS STEELS

- HIGH-STRENGTH STEELS

- LIGHT ALUMINIUM ALLOYS USING A PRESS FLEET FOR WHICH THERE ARE FEW COMPARISON IN THE REST OF EUROPE

MIG/MAG/TIG/SPOT WELDING/LASER WELDING

BONDING ON ROBOTIC ISLAND

2D/3D LASER CUTTING

CLINCHING ON ROBOTIC ISLAND

Solutions

From design to production to delivery, we are committed to working.

Aluminium – Car Body

METAL AND PLASTIC PARTS

For our customers, we produce cold moulded components in stainless steel, high-strength steel and light aluminium alloys:

- for sub-assemblies and systems that we assemble in-house:

- as direct supply components.

METAL/STRUCTURAL/AESTETHICAL COMPLEX ASSEMBLY AND SYSTEMS

40 years of production experience and technological evolution allow us to assure our customers the accurate production of sub-assemblies and systems for the automotive industry, assembled with the most modern and high-performance technologies.

We have participated in the technological evolution of the market by developing skills and experience in complex assemblies of a structural (body, seats, interiors, etc.), functional (exhaust systems, braking systems, etc.) and aesthetic (bodywork, finishes) nature.

In addition, always in line with market requirements, we have developed the technology and knowledge to build chassis for the hydrogen tanks of fuel cell vehicles; a new challenge that we have taken on with enthusiasm and expertise.

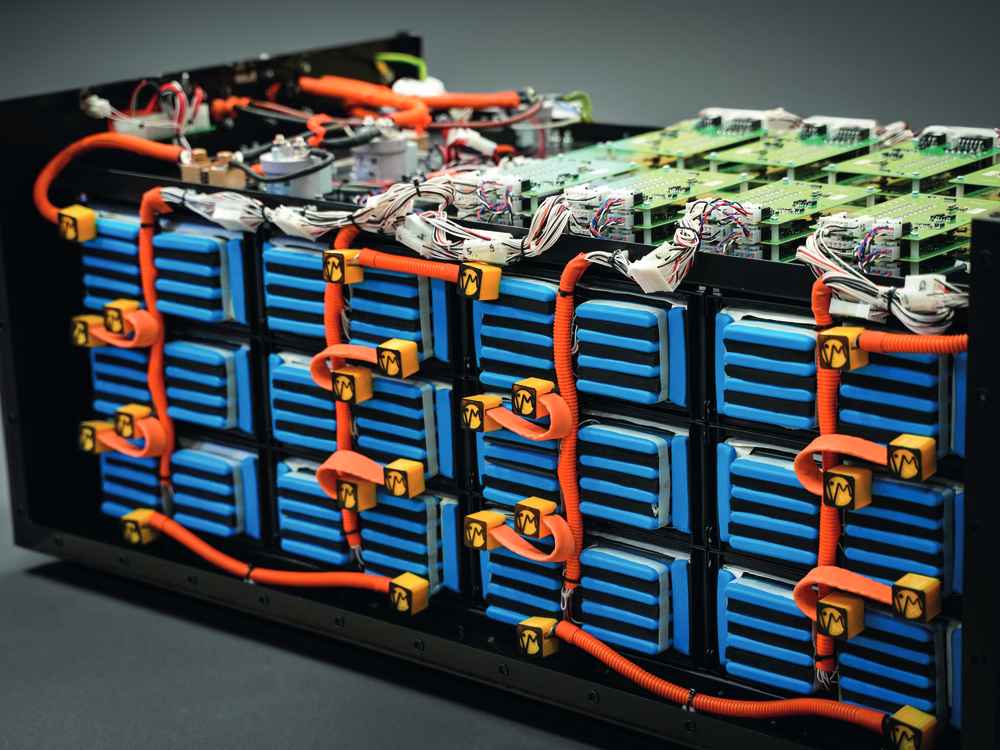

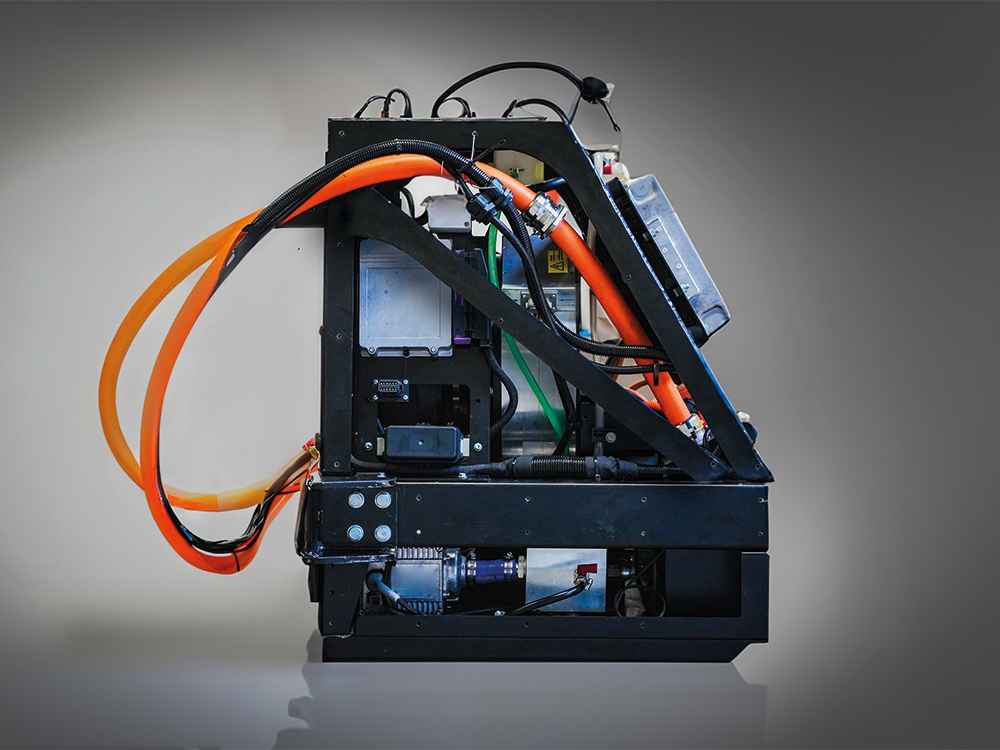

BSS - BATTERY STORAGE SYSTEMS AND THE WHOLE ELECTRIC/HYBRID DRIVE TRAIN SYSTEMS & CHARGING EQUIPMENTS

Voltmec is able to design, develop and manufacture lithium battery systems for the most diverse uses in the field of electric vehicles, AGVs and electric industrial machines in various sectors.

Voltmec’s know-how allows the company to understand customer specifications in the best possible way, using the most innovative technologies available on the market, from the R&D step through to series production.

Voltmec is a technological partner able to support customers in the development of innovative products also through advance engineering and prototype production.

Our product lines are: customer-specific lithium battery systems, standard lithium batteries available in the Voltmec catalogue, complete drive-trains, PDU power distribution units, OBC on-board battery chargers, power packs, charging stations.

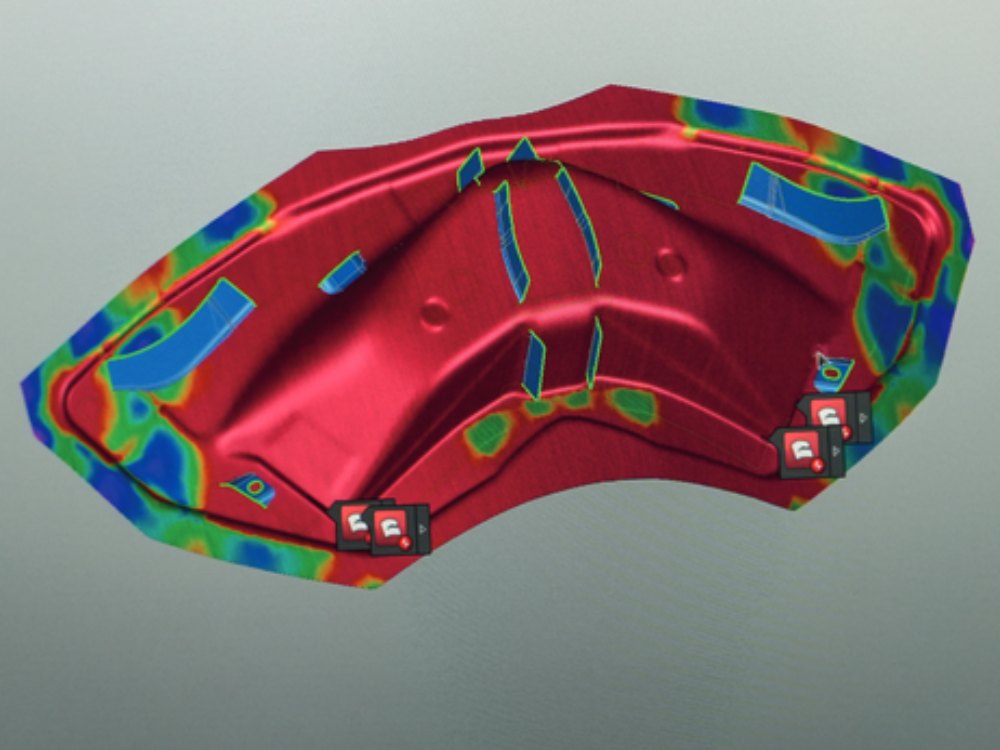

CO-DESIGN DEVELOPMENTS

RFQ – Request for Quotation, but that’s not all: one of P&C System’s strengths lies in its ability to develop new tailor-made projects together with its Customers, collaborating with them in overcoming technological limitations and non-feasibility issues. This is not just a service, but a proven approach that allows for tailor-made results, better performing and better suited to each customer’s needs. This is an investment in effectiveness and reliability, which significantly reduces the time needed to revise and modify each component. Our group makes its know-how available to customers to help them develop the ideal product, optimising technical feasibility and costs thanks to our studies and simulations.