Technologies

Our continuous pursuit of excellence, combined with our advanced technological solutions, enables us to deliver highly customized components. Every stage of the production process is optimized to ensure quality, precision, and efficiency.

ROBOTIC ASSEMBLIES FOR THE SUPPLY OF SYSTEMS AND SUB-ASSEMBLIES

We employ robotic assemblies for the production of systems and sub-assemblies, ensuring high precision and repeatability, shortening production times, and optimizing the quality of the final product.

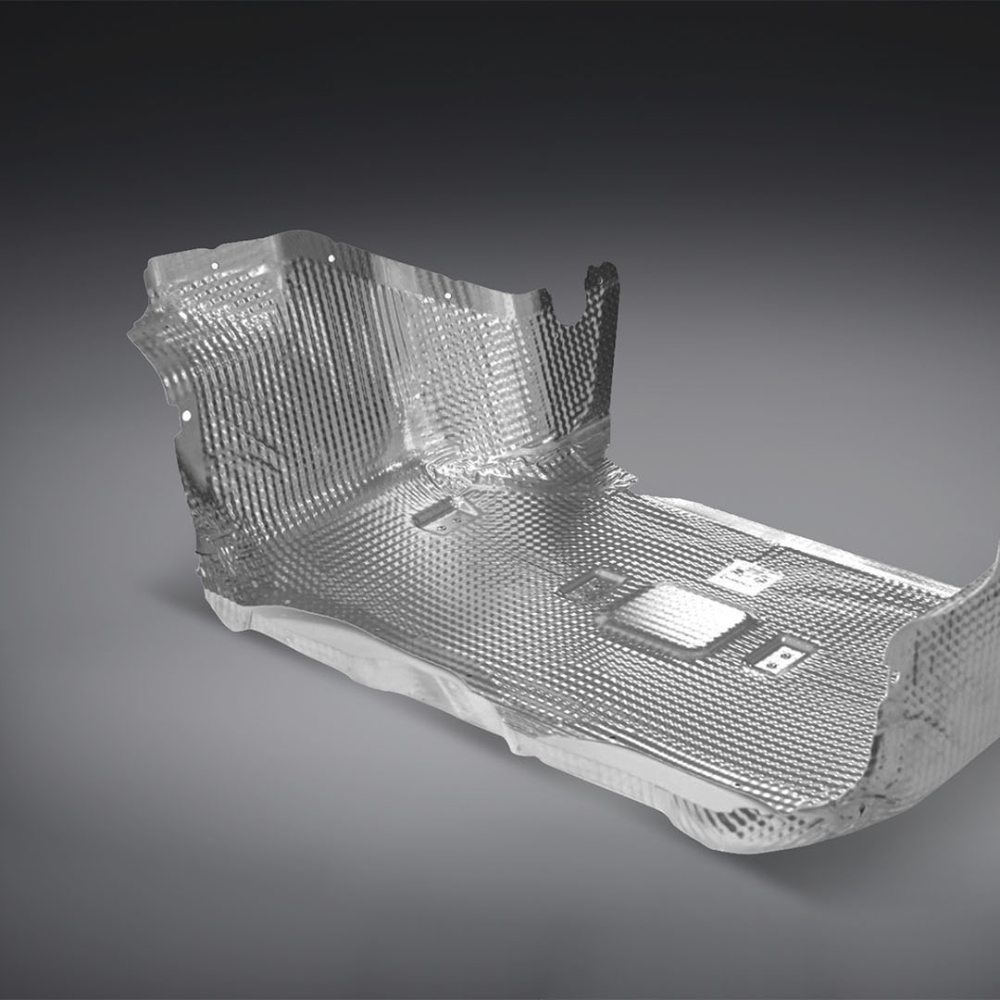

COLD STAMPING

With one of the largest production capacities in Europe, our press fleet can cold-stamp stainless steel, high-strength steels, and lightweight aluminum alloys.

MIG/MAG/TIG/SPOT/LASER WELDING

We offer advanced welding solutions, including MIG, MAG, TIG, Spot, and Laser, to ensure strong and precise joints across a wide range of materials.

ADHESIVE BONDING AND CLINCHING ON ROBOTIC CELLS

Our robotic cells for adhesive bonding and clinching enable fast, precise operations, ensuring the reliability and durability of the final components.

2D/3D LASER CUT

State-of-the-art 2D and 3D laser cutting enables precise, rapid material processing, guaranteeing extremely tight tolerances and flawless finishes.

SHEET METAL ASSEMBLY FOR BODY MODULES

Our sheet-metal solutions for body modules provide exceptional quality and robustness, essential for the production of high-performance automotive components.