P&C System

Group

we are able to provide effective and localised support in the areas where our customers operate, ensuring agile and effective project management.

A comprehensive and

transversal know-how

The strength

of the group

A solid industrial journey that began in 1979 led to the founding of P&C System in 2016. Today, P&C System is an International Group that stands out for its presence based on 7 production plants located in the main strategic industrial areas in Europe, also allowing effective coverage of supplies to the American and Asian markets.

We provide Solutions for:

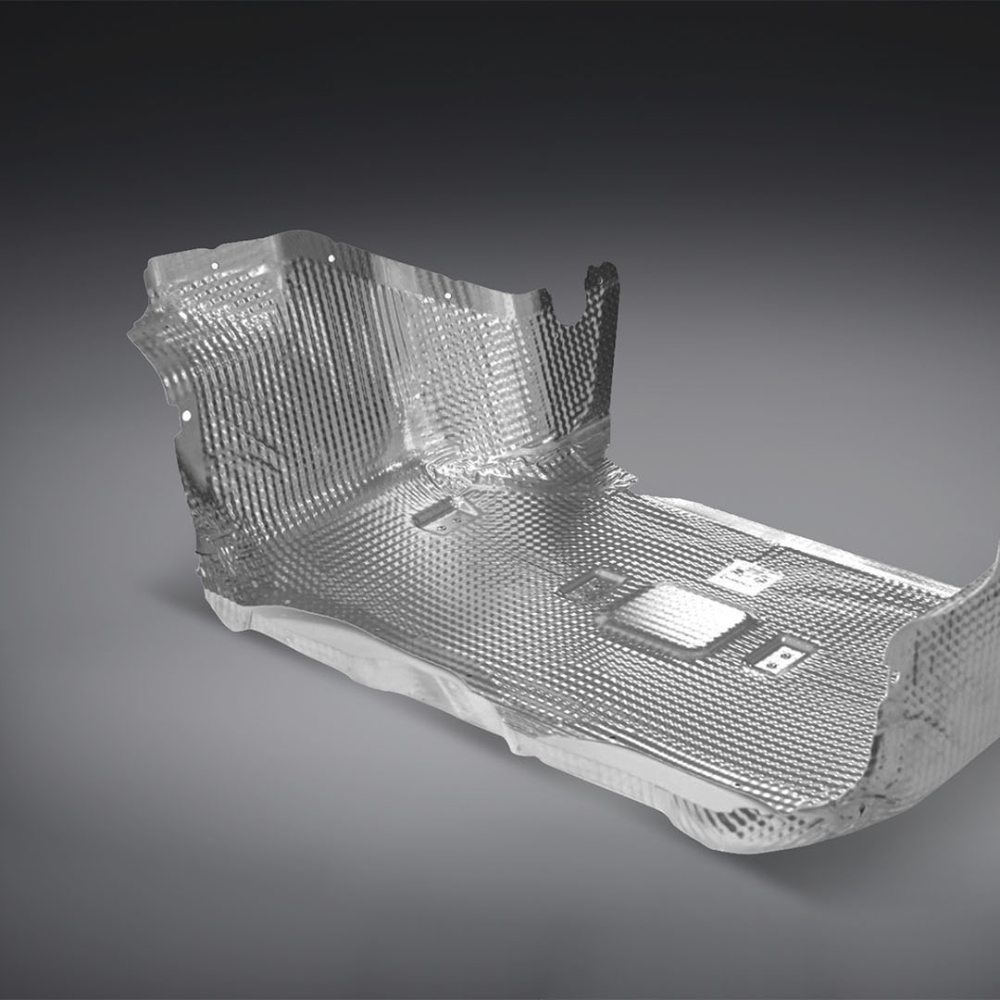

• Metal and plastic components

• Assembly and complex metal systems for structural and/or aesthetic purposes

• Vehicle and work vehicle electrification (batteries, PDUs, Chargers, Power Packs, etc.)

• Skill development in Co-design

Main Company Drivers:

• Battery / e-Mobility Market

• Automotive Systems Market

• Environmentally Driven Industry

• CTO – Cost & Tech Optimisation

• Acquisitions – Innovation & Technology

Evolution of

the Group

For us, Evolution is a constant.

We have embraced the concept of change as an integral part of our corporate identity, ensuring that we always remain one step ahead.

Plants

R&D centres

SQM Surface Area

People

Technology that generates Value

The characteristics that set us apart are: Flexibility. Proactivity. Dynamism. Competitiveness.

Trusted by

Milestones

Italy

1979

In the heart of one of Italy’s most industrial and mechanical districts, Lecco, CATRA is founded.

It is a company specialising in the cold pressing of metal products that, over time, focused on the production of components and sub-assemblies for the automotive sector.

Italy

1997

Bulgaria

2004

SILPA focuses on the production of metal components and injection moulding of plastic products. The constant willingness to improve and attention to detail characterise every stage of the production process, guaranteeing reliable, long-lasting results.

Germany

2011

Production in the Klipphausen plant near Dresden is completed and started. P&C thus enters the leading European automotive market.

Romania

2013

On the Group’s constant path toward internationalisation, in 2013 a new production plant was inaugurated in Romania, specifically in Giurgiu, near Bucharest and close to the border with Bulgaria, a region characterised by a significant industrial vocation.

Portugal

2015

Established in 2015 in Bragança, CATRAPORT represents the tangible result of the internationalisation process that has seen Catra and the entire Group expand at European level with a targeted and well thought-out strategy.

Italy

2016

P&C Automotive is the headquarters of our group. The company was founded in 2016 to take on the role of coordinating the network of companies that make up our network, and is the hub that capitalises on the group’s vertical integration strategy.

P&C System

2021

Working as a system to face and win the new challenges in the automotive market: to achieve this, the P&C Group changes its name to P&C System.

Italy

2022

With the idea of continuous expansion and evolution, Voltmec joins the group. A leader in the innovation of solutions such as lithium battery systems, complete electrical transmission systems and charging systems, from the conceptual phase, through design and validation, to the production and delivery of components.